The sample preparation laboratory carries out preparation of every type of material to make it suitable for electron microscopy. The laboratory hosts all facilities necessary for adapting them to the requirements of every electron microscope, either for scanning electron microscopy (SEM) or for transmission electron microscopy (TEM).

Flat and smooth surfaces are required for good quality images and chemical contrast in SEM. LMA has tuned up the automated grinder-polisher Buehler Phoenix Beta, specially designed to polish multiple samples embedded in resin. In addition, a wide range of resins is offered, readily available for samples which can stand or cannot stand heat during resin polymerization.

With the aim of achieving a flat and homogeneous surface in soft samples, the LMA has a diamond knife specially designed for semi-thin sectioning (~ 1µm of thickness).

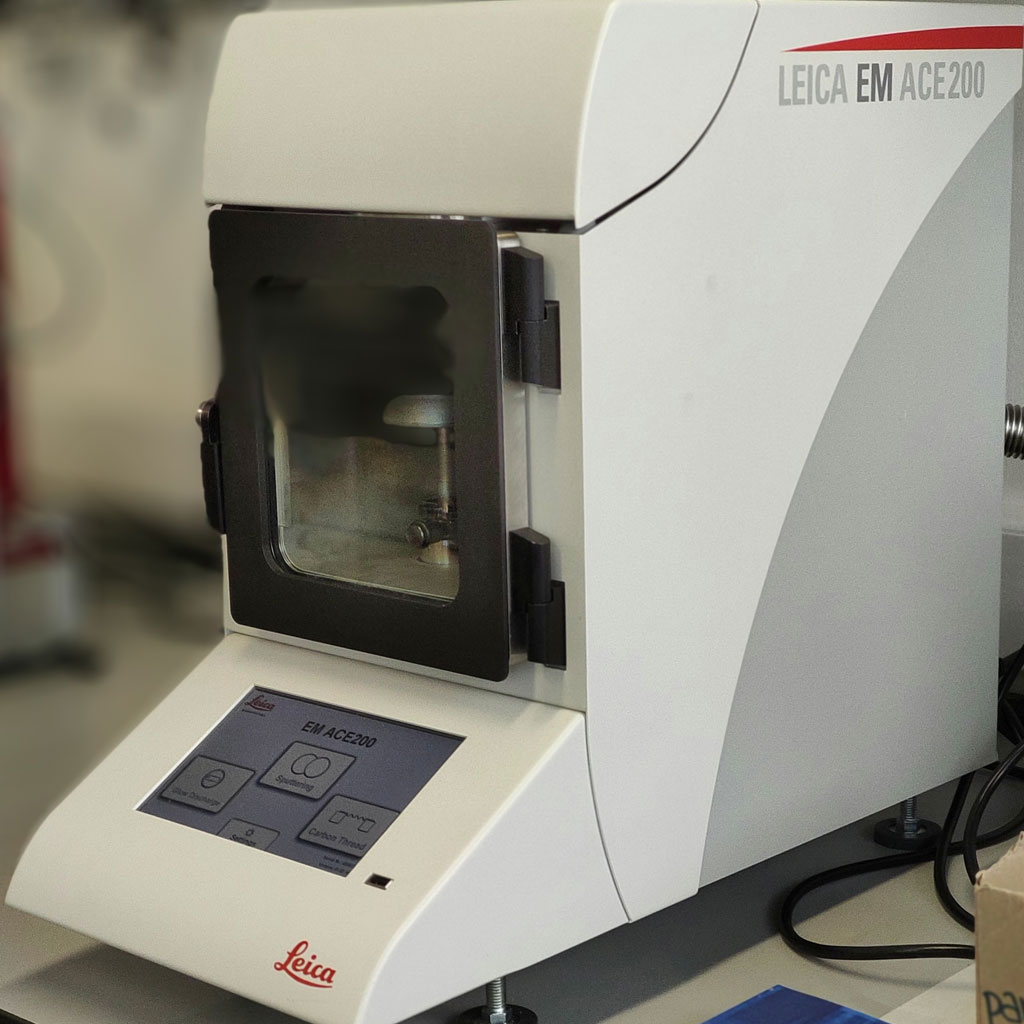

oConductive coating of samples are achieved by the vacuum coater Leica EM ACE200. A planetary drive stage is available for coating samples with irregular surfaces.

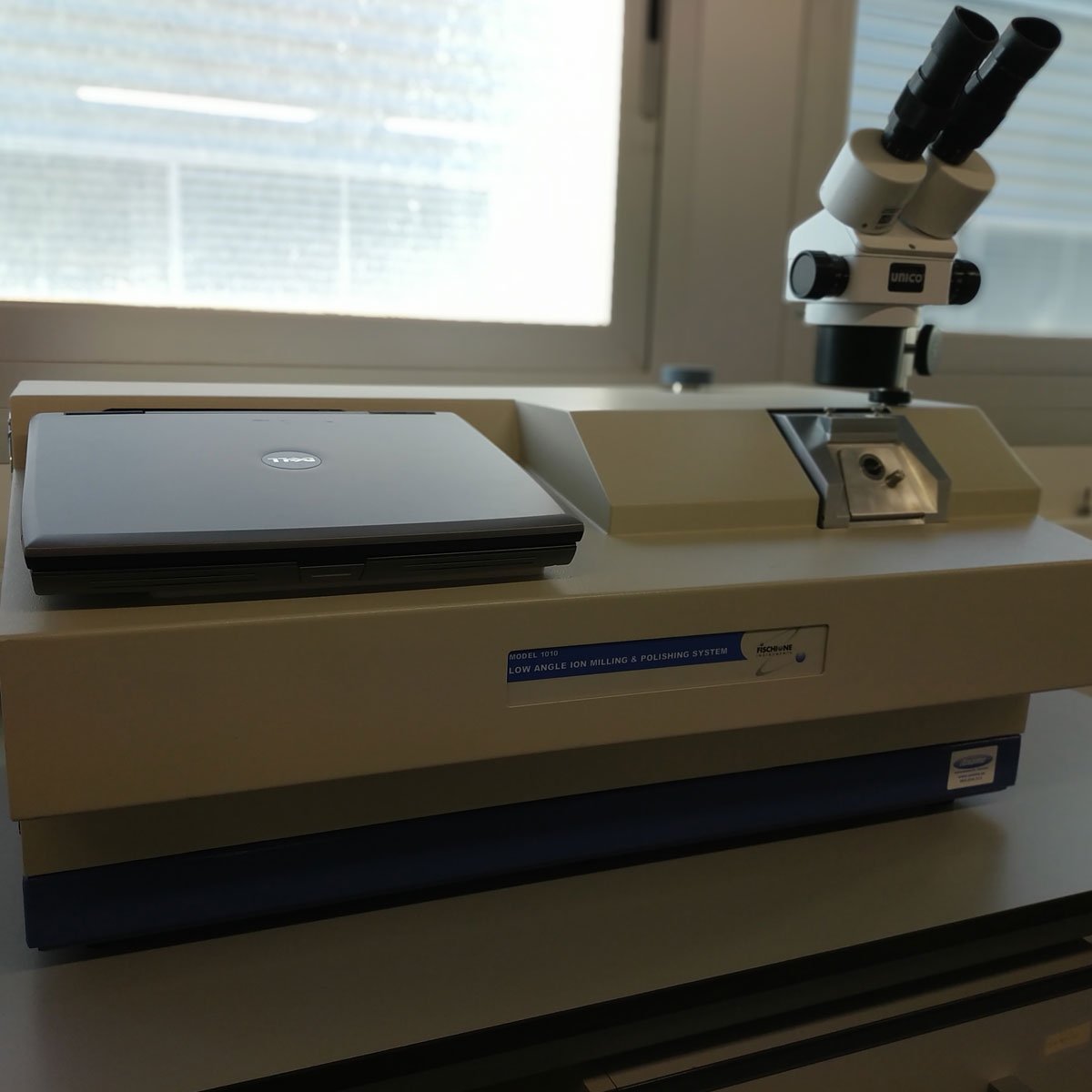

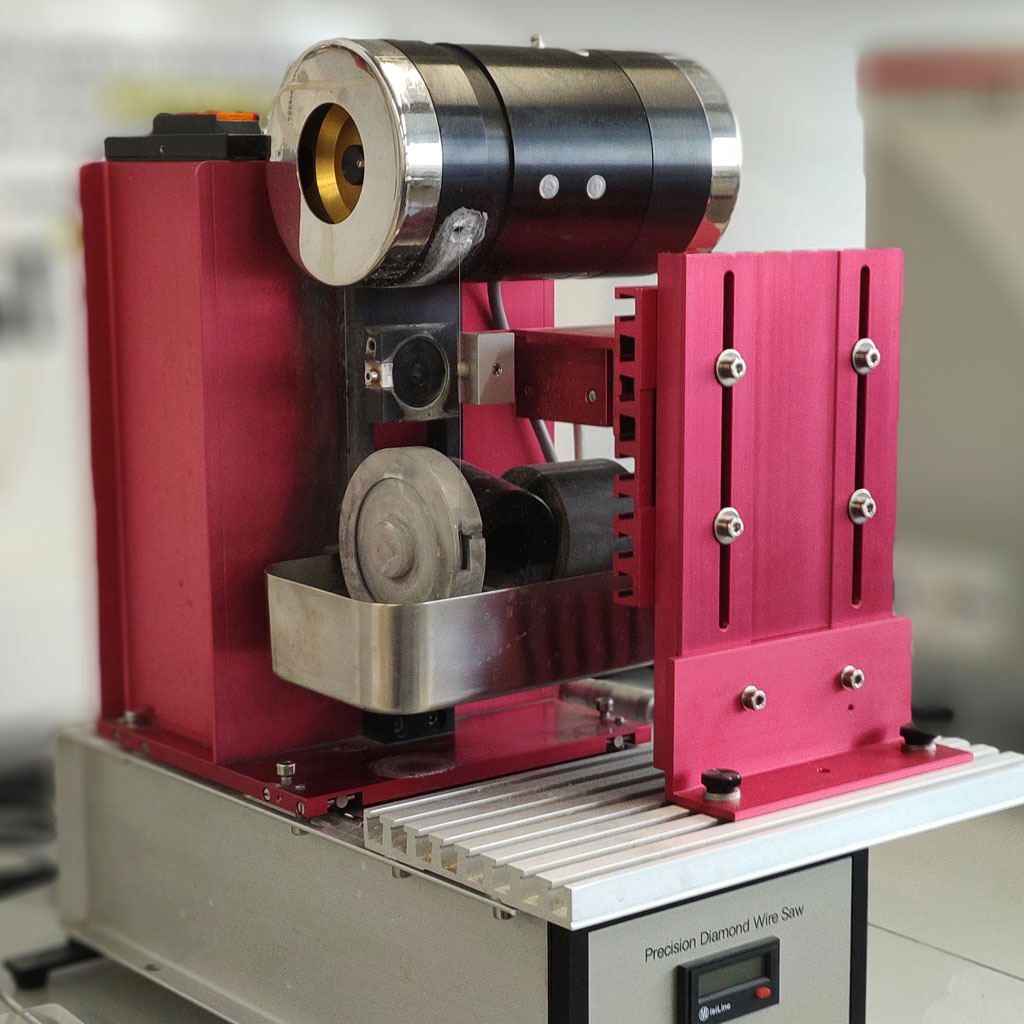

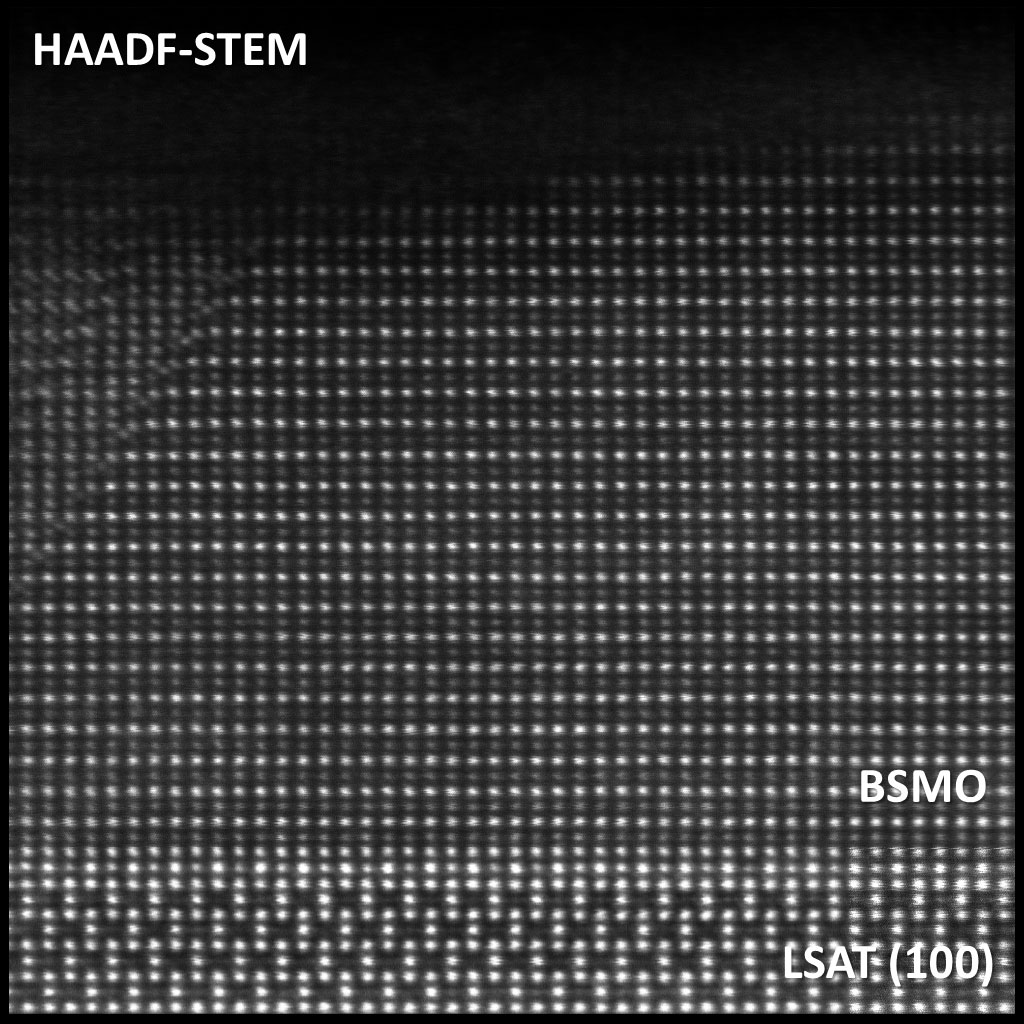

A prerequisite in TEM is that samples must be thin enough so that the electrons (tipically < 100 nm) can pass through. Mechanical thinning of cross-sections and planar views in a highly controlled way, with a diamond wire saw and a tripod polisher, in combination with low-angle and low-energy ion milling, produces a flat specimen of a few microns in thickness, with defect-free surfaces and areas ready for TEM observation.

Ultramicrotomy is another technique to produce 50-70 nm thick slices of soft (biological, inorganic and composites) materials. Depending on the specific features of materials, samples can be sectioned between -180 °C (cryo-ultramicrotomy) and room temperature. Regarding biological samples (tissues, cells, bacteria, etc.), two types of sample procedures are applied, depending on the sample and analysis requirements:

– Standard treatment: samples are chemically fixed (i.e. glutaraldehyde and osmium tetroxide), dehydrated and embedded in epoxy resin before slicing them with the ultramicrotome.

-Tokuyasu method: samples already fixed are embedded in gelatine, infiltrated with sucrose, then frozen in liquid nitrogen and sectioned by means of cyo-ultramicrotomy. It is the most reliable and sensitive method for immunolabelling.

Biological or polymeric material to be characterize by SEM or TEM sometimes need heavy metal staining to increase contrast and ease observation. In the LMA, we have several staining agents at disposal: osmium and ruthenium tetroxide, uranile acetate, lead citrate, phosfotungstic acid, methyalmine vanadate and methyalmine tungstate.

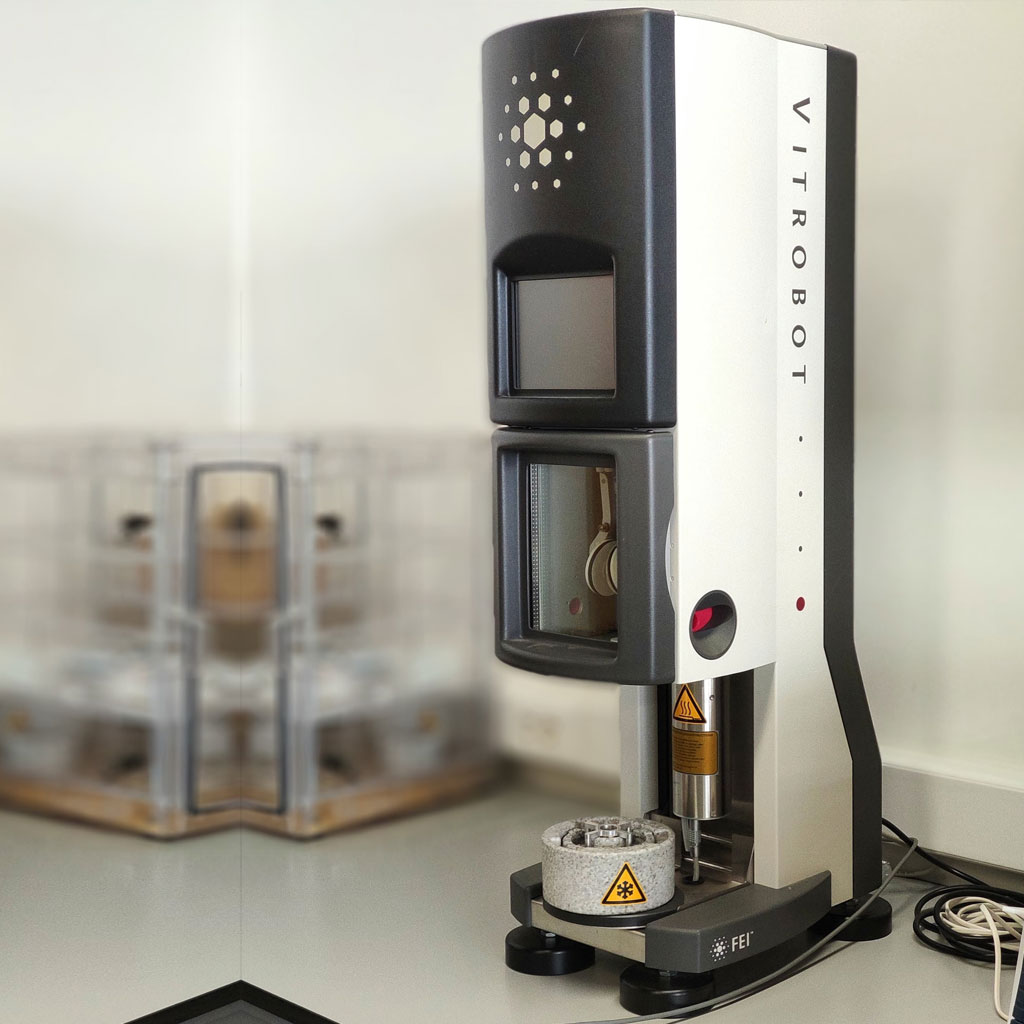

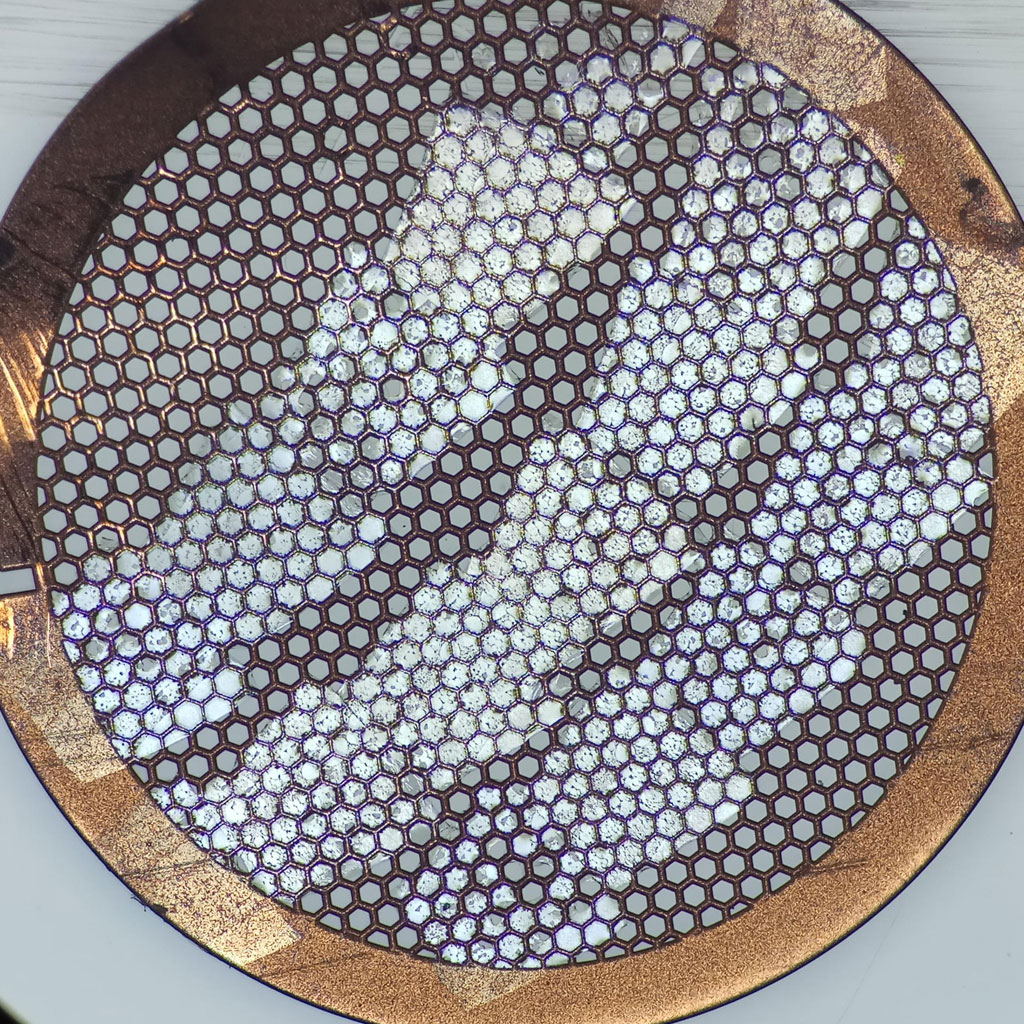

Vitrification of samples and their analysis in cryogenic conditions is other outstanding technique available in LMA. Cryo-TEM is a good alternative for the direct observation of liquid samples in its original state: specimens are vitrified in liquid ethane or propane and analysed in the microscope at low temperature. The vitrification method is based on a very fast sample cooling that prevents the formation of crystalline ice. Moreover, the thin layer of amorphous ice formed during the vitrification process protects the material from electron beam damage. The vitrification process is achieved in an Thermofisher Vitrobot©: A 3 µl drop of an aqueous suspension of the material is placed on a TEM Quantifoil© carbon grid, the excess of water is blotted away at the Vitrobot© with filter paper and the grid is freeze-plunged in liquid ethane. Samples are then transferred under liquid nitrogen atmosphere to a Gatan TEM cryo-holder equipped with a liquid nitrogen reservoir. In that way samples are handled and observed at T=100K.

The vacuum coater LEICA EM ACE200 is equipped with a glow discharge option to make grids temporarily hydrophilic and allow aqueous solutions to spread easily.

- Ion Mill Fischione, model 1010.

- Plasma Cleaner Fischione, model 1020.

- Low/high-speed polishers.

- Tripods and grinders.

- Diamond wire saw Well, model 3242.

- Precision Sectioning Saw Buehler, model IsoMet 1000

- Stereographic, metallographic and inverted microscopes.

- Leica EM Trim

- Ultramicrotome Leica EM UC7.

- Cryo-ultramicrotome Leica EM FC7.

- Leica EM KMR3 .

- Diamond knives Ultra 35°; Cryo 35°; Cryotrim 45°; Histo 45°

- Leica EM ACE200 coating system (C, Pd) with glow discharge and planetary drive stage.

- FEI Vitrobot (vitrification).

- Printed circuit boards, microelectronic devices, etc.

- Nanoparticles, nanotubes, nanofibers, etc.

- Polymers and composites.

- Inorganic materials (oxides, metals, ceramics, porous) in cross-section and plane view.

- Organic molecules (proteins, DNA, gels, virus, …).

- Cells and biological tissues.

Laboratorio de Microscopías Avanzadas

We are a unique initiative at national and international levels. We provide the scientific and industrial community with the most advanced infrastructures in Nanofabrication, Local Probe and Electron Microscopies for the observation, characterization, nanopatterning and handling of materials at atomic and molecular scale.

Contact information

Campus Río Ebro, Edificio Edificio I+D+i

Direct Links

© 2021 LMA | Website developed by o10media | Política de privacidad | Aviso legal | Condiciones de uso | Política de Cookies |