The clean room is a laboratory that consists of several spaces areas with a temperature- controlled environment and with highly-demanding air filtering to limit the number of suspended particles and thus ensure a very high level of cleanliness. 25 m2 are classified as class 100 (ISO5) and 100 m2 as class 10,000 (ISO7). The class number indicates the quantity of particles per unit volume, in a laboratory without treatment this quantity is higher than 1,000,000.

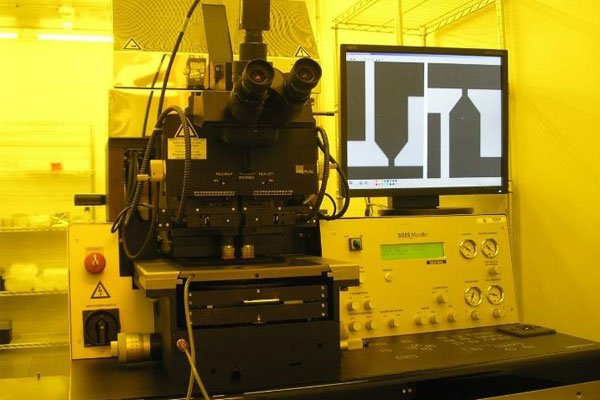

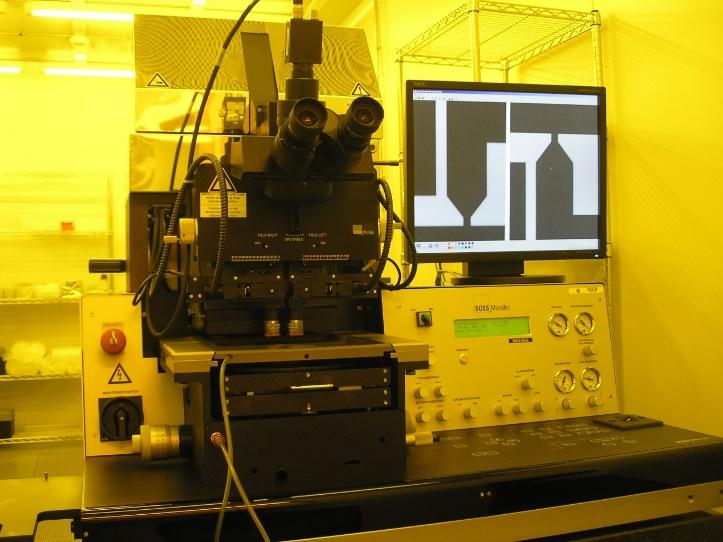

The optical photolithography laboratory is located within class 100, and has instruments that allow defining structures with a lateral size of updown to 1 micrometer in photoresist on 4-inch wafers or smaller substrates.

Equipment

- Süss Microtech MA6 mask aligner,

- Spin coater from Süss Microtech,

- Wet chemical bench for sample cleaning and resist development

- Zeiss Axio Imager optical microscope for visual inspection.

Süss Microtech MA6 mask aligner

Sistec RIE & IBE

Boc Edwards E-Beam PVD

Perfilómetro mecánico KLA-Tencor P6

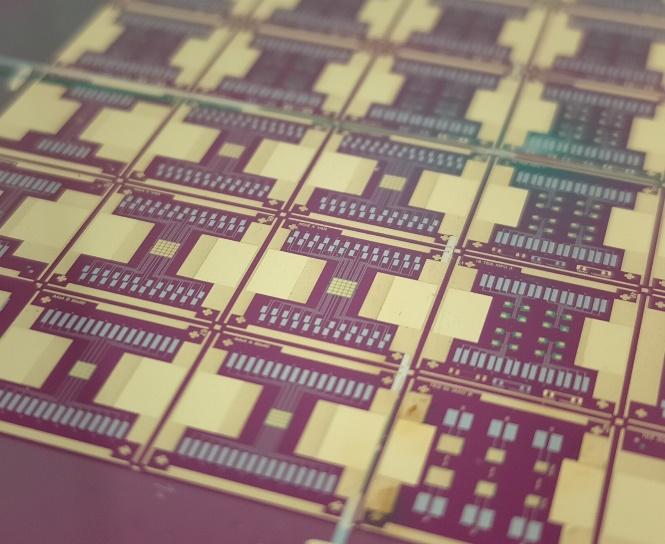

4” wafer with microsystems fabricated in the clean room of the LMA.

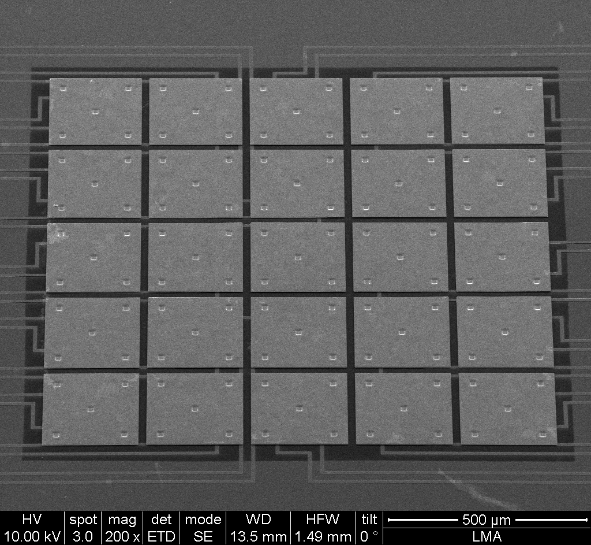

SEM image of the central area of one of these microsystems.

Laboratorio de Microscopías Avanzadas

We are a unique initiative at national and international levels. We provide the scientific and industrial community with the most advanced infrastructures in Nanofabrication, Local Probe and Electron Microscopies for the observation, characterization, nanopatterning and handling of materials at atomic and molecular scale.

Contact information

Campus Río Ebro, Edificio Edificio I+D+i

Direct Links

© 2021 LMA | Website developed by o10media | Política de privacidad | Aviso legal | Condiciones de uso | Política de Cookies |